Products

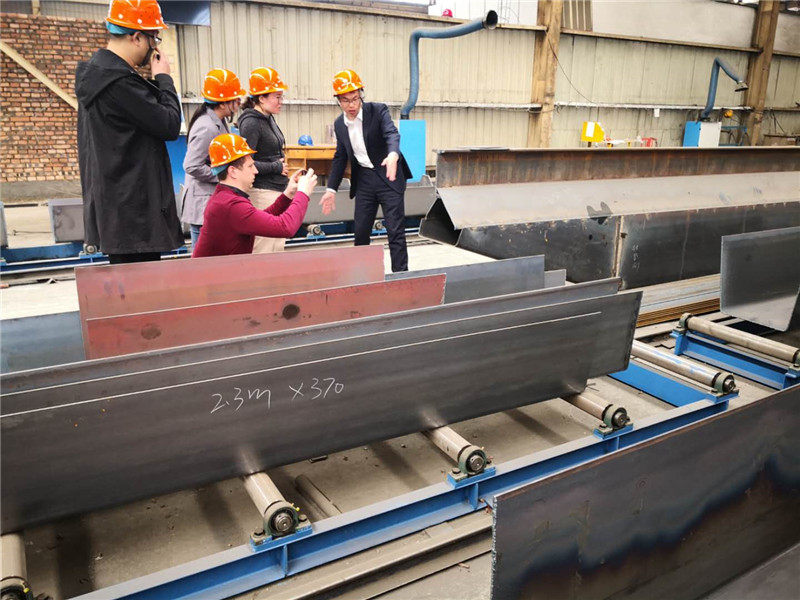

Railway Bridge Concrete Girder launching gantry Erecting crane 200T

1. Reliable performance

a) Apply the latest separate pinned structure of triangular space truss to main girder, so as to improve the stiffness and strength of whole crane.

b) Main girder is made of Q345 high strength steel, and melt into the latest design to ensure the main girder can work under high strength mode safely.

c) Modern crane brand launching crane is pioneering in continuous one time operation during bridge launching progress in China. It is of the most complete function launching crane for single machine domestically.

d) Compared with similar products from other supplier, Moderncrane brand launching crane have its unique design concept to the most difficult hole-span during bridge erection, in the way of laying side beam. So, it is safer to operate under high difficult and risk condition.

e) Powerful front, middle beam and three transom crane connect together to ensure transverse stability during bridge erection fully.

f) There is separate stroke switch control to each traveling mechanism, so as to decrease mutual collision between each traveling mechanism.

g) Overload resistance system: there is high performance weight limiter on two sets of trolleys, so if the lifting girder is overloading, the weight limiter will stop it at once.

h) There are normally three legs from other supplier. But we have four legs, including one front leg, one middle leg, one rear leg and one temporary leg.

i) Apply inner shrink leg to one time erect side beam in position and have more safety.

2. More powerful corrosion resistance

a) Strictly execute standard painting process to ensure blasting and painting quality.

b) Apply H steel enclosed section for main girder chord. Web chord is made by customized square tube to realize enclosed welding, which can avoid inner rust.

3. Higher working efficiency

a) There is traveling rail together with main girder, trolley and longitudinal crane. So, it is no need to lay traveling rail more. In this way, a lot of auxiliary materials are saved and production time is also saved.

b) Modern crane launching crane has higher working efficiency, with 6~8 pieces girder erection every day, based on enough concrete plate supplying, skilled operator and good condition at site.

4. More flexibility

a) It is symmetrically designed. Two way girder erections can be realized without split and slewing at original place.

b) Use one meter of hydraulic jack for front leg and rear leg. This design improves working efficiency, safety and flexibility largely.

c) Erect skew bridge by inclined way. Apply rotary face flange to connect each mechanism and structure, to erect 0~45°skew bridge. Side beam can be positioned one time for over 320m curve radius bridge.

5. Easier assembly and disassembly

a) Each structure is connected by pins and bolts to facilitate assembly.

b) Normally one set of launching crane can be assembled within 7days.

| Item | Data |

| Capacity | 30-500t |

| Bridge radius | 20-50m |

| Slope | below 1/20 |

| Turning radius | 200-350m |

| Angle of skew bridge | 0-15° |

| Shop travelling speed | 2-45m/mim |

| Crane travelling speed | 2-50m/min |

| Power source | as your demands |

| Other | According to your specific usage, specific model and design will offer |

About KORIGCRANES

KORIGCRANES ( HENAN WEIHUA KORIG CRANES CO., LTD) located in crane hometown of China (cover more than 2/3 crane market in China), who is a trusted professional industry crane manufacturer and leading exporter. Specialized in design, manufacturing, installation and service of Overhead crane, Gantry crane, Port crane, Electric hoist etc, we have passed ISO 9001:2000, ISO 14001:2004, OHSAS 18001:1999, GB/T 19001-2000, GB/T 28001-2001, CE, SGS, GOST, TUV, BV and so on.

Product Application

To meet the demands of the oversea market, we independent research and development European type overhead crane, gantry crane; electrolytic aluminum multi-purpose overhead crane, hydro-power station crane etc. European type crane with light dead weight, compact structure, lower energy consumption etc. Many main performance reach the industry advanced level.

KORIGCRANES Widely used in machinery, metallurgy, mining, electric power, railway, petroleum, chemical, logistics and other industries. Service for hundreds of large enterprises and national key projects such as China Datang Corporation, China Guodian Corporation, SPIC, Aluminum Corporation Of China(CHALCO), CNPC, Power China, China Coal, Three Gorges Group, China CRRC, Sinochem International, etc.

Our Market

Our cranes has been exported cranes to more than 110 countries for example Pakistan, Bangladesh, India, Vietnam, Thailand, Indonesia, Philippines, Malaysia、USA, Germany, France, Australia, Kenya, Ethiopia, Nigeria, Kazakhstan, Uzbekistan, Saudi Arabia、UAE、Bahrain、Brazil, Chile, Argentina, Peru etc and received good feedback from them. Very happy to be friends with each other come from all of the world and hope to establish long-terms good cooperation.

KORIGCRANES has steel pre-treatment production lines, automatic welding production lines, machining centers, assembly workshops, electrical workshops, and anti-corrosion workshops. Can independently complete the whole process of crane production.

Q. What’s the information should I provide when inquiry?

More details or drawings, better.

A: Lift capacity B: span C: lift height D: power source; other specials you give us will be more appreciated.

Q. How many operating methods for my selection?

Standard operating methods:

A: remote control with push buttons

B: cabin (space capsule seat) control with joystick. Choose any type as you like.

Q. Can this type work in hazardous environment?

A:Sure! We can customize for you, acid proof or explosion proof, no problem for that.

Q. Can you provide the serious lifting tools?

A:Sure, we can provide any lift tools such as lift sling belt, lift clamp, grab, magnet or other specials as your requirement!

Q. How can we install the crane?

A:Our senior engineer can be your side to do the installation guide service and training. Moreover, our best sales can visit your country.